News

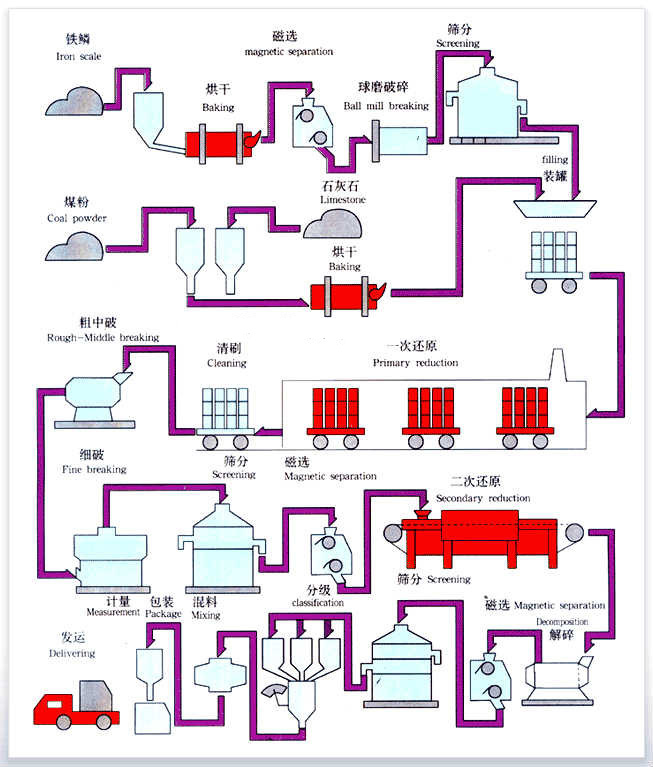

Reduced iron powder flow chart

Secondary reduced iron is actually referring to the recovery method starting pig iron. Recovery Act means having to melt while the recovery of iron ore in a blast furnace at high temperature molten state approach , which is a component of goods and liquid molten hot metal nearby . Intent is to develop an alternative method of melting recover or compensate for blast furnace ironmaking . Compared with blast furnace ironmaking process , molten iron method has the following characteristics :

( 1 ) fuel instead of coal coke, coke oven time to build , to reduce pollution .

( 2 ) can be used as blast furnace lump iron ore to make direct use of material or materials . Such as the use of slag as a material , may build sintering plant or pellet plant .

( 3 ) all with oxygen instead of air, oxygen consuming large .

( 4 ) can be output with the hot metal composition, temperature molten fundamentally the same for steelmaking .

( 5 ) In addition to the production of hot metal , but also occurs in many of the high calorific value gas .

Recovery Act melt many current world , as long as the Corex method during seasoned skills match the scale of industrial production has been constituted , the other dharmas still ongoing and the process of industrialization . Recovery Act melt in China has not been a great launch , currently in laboratory experiments during and semi-industrial experiments.

Secondary effect of reduced iron :

Reduced iron powder is widely used in secondary metallurgy products , oxygen scavenger , purifying agent , auto parts manufacturing, medicine, and brake pads production welding , cutting and other professional and electrical . During metallurgy products accounted for about 70 %. ( Note: The special welding iron recovery , participated in 10% -70 % iron in the coating can be useful to improve the welding rod welding technology and significant progress deposited power .